“Bonsai Jacks” are tools designed to bend heavy branches and trunks. They allow us to make these bends incrementally – and safely – by twisting a threaded rod.

The best way to describe their use is with an example, so let’s start there. Here’s a pine styled by Daisaku Nomoto with help from Boon Manakitivipart, Matt Reel and Tyler Sherrod at the 2016 Pacific Northwest Bonsai Convention held in Olympia, Washington.

Daisaku Nomoto and Boon Manakitivipart after the demo

Daisaku bent the trunk of the pine significantly during the demonstration, but he noted that he wanted to bend the trunk further once the tree had recovered from the work. I acquired the tree at the event and found the perfect opportunity to complete the bend as Daisaku is currently visiting California. Here he is modeling the jack he’ll be using on the pine.

Daisaku and the bonsai jack

And here is a photo of the pine before making the bend.

Black pine, January, 2018

The first step is to prepare a wire loop that the jack can use as an anchor to make the bend.

Wires used to anchor the jack

In this case there are two wire loops. The first loop encircles a root as an anchor point. The second, longer, loop makes it easy to anchor the jack without it bumping against the trunk and provides some flexibility for changing the length of the anchor wire without re-doing the section around the root.

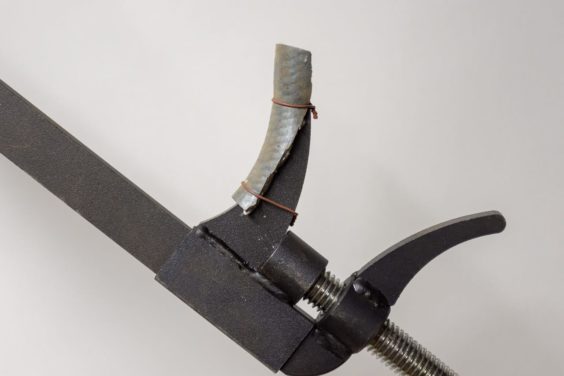

The other end of the jack will grab the trunk directly. To provide some protection where the jack touches the trunk, Daisaku added a piece of rubber hose secured with small copper wires.

Section of rubber hose covering the sharp edges of the jack

Here is a photo of the setup before starting the bend.

Ready to begin the bend

And here’s a close-up of how the jack fits into the anchor wire.

The jack inserted into the the anchor wire

Twisting the jack begins slowly. While making the bend, common practice entails listening carefully to any cracks or pops that may occur along the trunk or branch being bent. It’s also important to monitor the rigging to ensure that nothing slips out of place during bending.

Here’s a close-up of the guy wire and anchor wires after starting to bend the trunk.

The anchor wire is taut – the original guy-wire is now loose

As the tightening continued, it became clear that we needed to make some adjustments. Bringing the trunk down lowered the guy wire below the lip of the pot. We added a piece of rubber below the guy wire to protect the pot and added a second guy-wire to maintain good leverage on the trunk.

When setting up the second guy-wire, Daisaku prepared a tube inside of a tube to protect the trunk from the wire cutting in. Here’s the tubing used for this.

A tube within a tube

Slots cut in the middle of the tubes where the guy-wire will emerge

We also found that the change in the angle of the trunk brought foliage close to the moving parts of the jack. Daisaku grabbed a sheet of paper to keep the foliage out of the way.

A sheet of paper protects the foliage below

Every so often, Daisaku paused to inspect the area of the trunk where the bend happened. He also tightened the guy wires to take up any slack that showed up.

Tightening the guy wires

Daisaku shared, at this point, a trick to ensure that the new guy wire was effective. Rather than making all of the bend at once, he made several twists, tightened the slack in the new guy wire with pliers, and then relaxed the jack. This made the new guy-wire taut and allowed him to inspect it to make sure it sat exactly where he wanted.

Without letting the pressure of the trunk take up the slack early on, the slack would come out when the jack is loosened and removed. Removing any slack in the line during bending ensures the trunk will stay in place when the bending is complete.

You can see the progress made after a few minutes of bending by checking the length of the twists in the guy-wires.

Evidence of a big bend

Of course, the difference was much more evident when viewing the front of the tree.

After completing the bend

Such a big bend necessitated a new potting angle.

The new potting angle

Only a single, additional bend was made to achieve this new trunk line. Here’s a close-up of a guy-wire that pulled the lowest part of the trunk forward.

Guy-wire in the tree’s interior

As there wasn’t time to repot the tree after making the bend, Daisaku created a chopstick framework that will make it easy to recreate the angle at a later date.

Chopsticks indicate the new angle

View from the side

For a better perspective on the actual shape of the tree, here’s a view from the side and back.

View from the right side

View from the back

The whole process took between 1-2 hours. When the work was done, we were both happy with the results.

I’ll repot the tree in the coming weeks and plan to re-wire the branches at decandling time in June.

Subscribe to Bonsai Tonight

New Posts Delivered Every Tuesday and Friday

Mac McAtee says

Most excellent post Jonas. It’s the little details that make things go smoothly and with a successful end. Many thanks for this.

Lani Black says

Please post a follow up after you repot and rewire this tree. I think we will see a dramatic change in the before and after pictures. Thanks!

Jonas Dupuich says

Thanks Lani, I’m planning on it!

Janny says

Hi Jonas, many thanks for this post and others, it’s wonderful to be able to learn from your documented work and thought process. One question: for that particular species and branch thickness, what length of time would you wait before you remove the bending wires? Or asked another way, how do you know when the branch is rigid enough to hold its new shape? Thanks!

Jonas Dupuich says

Good question Janny – I’d expect the trunk to hold a good percentage of the bend after two years. If the bend relaxes a bit, I can re-do the guy-wires to hold the trunk in place for another year.

In general, the faster the tree grows, the faster the bend will hold. Were this tree growing quickly (no decandling) in a large pot I’d expect the bend to set much faster.

Carol says

Thank you for this post! I bought a jack from you last year, but was afraid to use it as I didn’t understand how to do it without damaging anything. Your photos really make this clear.

Jonas Dupuich says

Thanks Carol – good luck with your future bending projects!

Michael Cole says

Thanks Jonus for the great coverage. Do you know what the “tube within a tube” material is?

Thanks, Mike

Jonas Dupuich says

Good question Mike – the larger tube is aquarium tubing, am not sure about the inner tube. Similar tubing is used to hold window screen into its frame but this tubing looks big for that. I tend to pick up scraps of tubing, sheets of rubber and sections of old hoses when I see them.

Bryan says

Is there any reason that a regular C clamp could not be used for this? Provided you could keep the branch from slipping off the swivel shoe

Jonas Dupuich says

Hi Bryan – I imagine a C clamp could work in some situations but would be too awkward for others. The jack does a good job of keeping everything where it needs to be for the bend to work.

Leonard Bell says

Very excellent detail Jonas. While you were in the bending process, were there sounds of stress ( tearing or splitting )?

Jonas Dupuich says

Hi Leonard – there were a few sounds during the first half of the bend, and plenty of small cracks during the second half.